- Mode:

SNFN1204

- Type:

Solid PCBN Inserts

- Application:

Automotive Industry

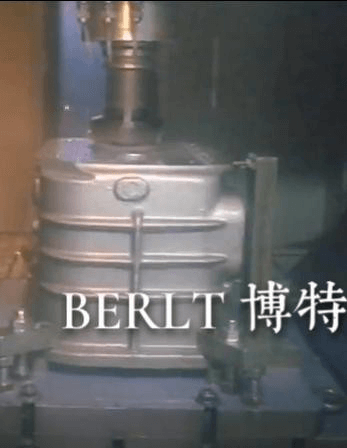

Application Of Berlt PCBN Inserts In Gearbox Processing

The transmission shell is equipped with transmission components such as input and output axle and gears, which are the core components of automobiles. The main role of the gearbox shell is to support the transmission axle and ensure the correct installation of the gearbox shell components and other components, so its processing quality directly affects the assembly accuracy and motion accuracy of the transmission assembly, and also affects the use of the car life. Therefore, in the process of processing the gearbox shell, the right inserts is particularly important.

At present, gearbox shell are mainly produced in batches. Due to the high-speed cutting, very fast wear will occur, resulting in shortened insert life. The use of traditional carbide inserts to produce gray cast iron gearbox shell is no longer in line with production requirements, and ultra-hard The development of materials has made PCBN inserts the first choice for processing gray cast iron gearbox shell. PCBN inserts can greatly improve production efficiency and product quality.

Case one:

Cutting tool manufacturer | Foreign coated alloy | Berlt zhengzhou |

Workpiece name and material | HT250(HB200-300) | |

Machining parts | Surface of shell | |

Insert model and material | SNMF43B2GF5020 | SNGN12041(BTS2800) |

ap(mm) | 2.5 | |

v(m/min) | 200 | 750 |

f(mm/min) | 950 | 2000 |

Tool life/pcs | 20 | 320 |

Processing quality | Ra3.2 | Ra3.2 |

Note: customer efficiency increased by 200%, tool life increased by 15 times | ||

Case two:

Cutting tool manufacturer | Foreign coated alloy | Berlt zhengzhou |

Workpiece name and material | HT250(HB180-250) | |

Insert model and material | TPKN2204 | SNFN120408(BTS2805) |

ap(mm) | 0.3 | |

v(m/min) | 197 | 664 |

f(mm/min) | 600 | 4000 |

Tool life/pcs | 20 | 320 |

Processing quality | Ra1.6 | Ra1.6 |

Note: the customer's efficiency is increased by 500%, the tool life is increased by 3 times, and the processing time per unit is 150s | ||

If you have any questions, please contact our Executive Manager and we will get back to you as soon as possible