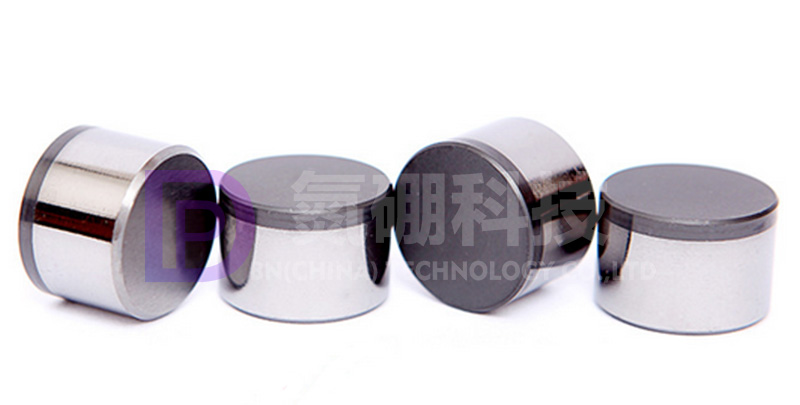

As a core component of modern drilling technology, the shape of diamond composite teeth directly determines the drilling efficiency, durability and applicable stratigraphic range. In this paper, we will discuss several common shapes of diamond composite teeth and their respective roles.

1. Flat Composite Drill Teeth

Flat composite teeth, as the name suggests, have a flat or slightly curved shape and are the most basic type of drilling teeth. This type of drilling teeth is widely used in the soil, sand layer of the open hole operation, because of its simple design, manufacturing cost is relatively low, suitable for dealing with the hardness of the ground is not high. Flat-blade drilling teeth have high cutting efficiency, but their durability and drilling efficiency may not be as good as other specially designed drilling teeth when facing hard rock formations.

2. slicing composite blade drilling teeth

Slicing composite teeth are characterized by the shape of their teeth being cut into thin slices, and each tooth seems to be cut with a knife. This design makes the teeth more effective in breaking up rock and improving drilling efficiency when drilling into harder formations such as gray rock. The carcass of a slicing tooth is usually thinner than that of a flatblade tooth to reduce weight and increase flexibility. In addition, the slicing teeth have additional teeth design, such as eight teeth slicing teeth, its drilling process is smoother, suitable for harder formations.

3. bread slice composite chip drilling teeth (ball slice composite chip drilling teeth)

Bread slice composite chip drilling teeth are also known as ball slice composite chip drilling teeth because of their slightly bulging shape, which resembles bread slices. These teeth are mainly used for drilling holes in pebbles or soil, and their wear resistance, durability and impact resistance are better than those of flat blades, so the price is relatively high. The special shape of the bread slice drilling teeth helps to disperse the impact force during drilling, improve drilling stability and durability, and is especially suitable for complex and changeable stratigraphic environments.

4、T-Tooth composite blade drilling teeth

The T-tooth composite blade drilling tooth is an innovative design characterized by the fact that the lip of the drilling tooth is flat bottomed before use, and the lip is formed into concentric crenellations (grooves) after using it for one cycle. As the diamond working layer wears out, the T-tooth teeth can gradually deepen the grooves of the concentric teeth, always maintaining the advantage of concentric teeth. This design can break the rock in front of the drill bit, forming multiple free surfaces, so that the drill bit not only grinds and crushes the rock, but also vibrates and breaks the rock, thus improving the drilling efficiency.T-tooth drilling teeth are especially suitable for drilling in hard and slippery strata.

5、Combined pinion composite piece drilling teeth

The design of combined pinion composite piece drilling teeth is more complex, its tooth shape with corrugated teeth, adapted to more hard strata, such as very hard gray rock and hard granite. The drilling efficiency of this kind of teeth is higher, and due to the reasonable design of the teeth, it can effectively reduce the radial oscillation of the drill bit, improve the stability of drilling and guiding.

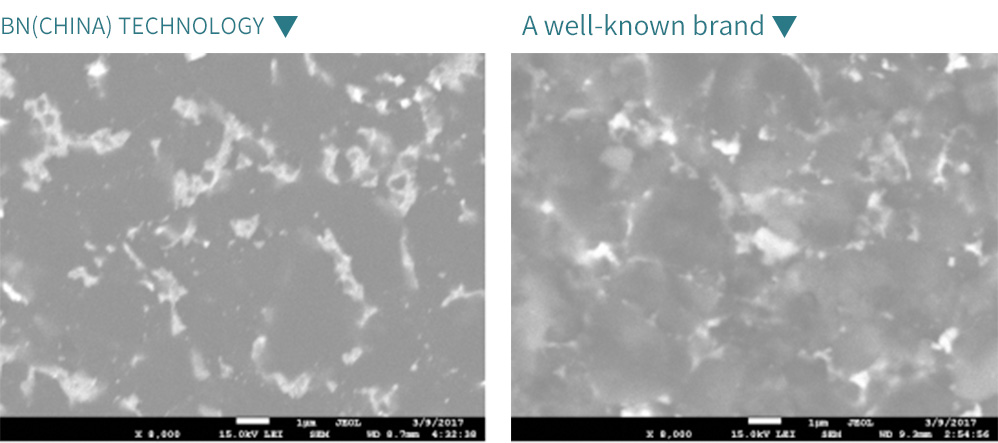

BN(CHINA) Technology Company adheres to the high quality products to win the market, so that customers can experience high-grade quality products at mid-range prices. The quality of BN(CHINA) Technologys' PDC materials is excellent, and the microstructure is comparable to that of foreign products. From the figure below, we can see that the bonding agent of Boron Technologies PDC material is uniformly distributed, the diamond particles are fused with each other, the bonding strength is high, the sintering is dense, and there are no air holes. Comparing with the microstructure of foreign products, BN(CHINA) Technology's products are consistent with similar foreign products.

Diamond composite pieces for oil and gas drilling of BN(CHINA) Technology Company have reached the international advanced level in terms of wear resistance, impact resistance and high temperature resistance, which can meet the needs of drilling in complex geological formations as drill cutting teeth for oil/gas drilling projects.BN(CHINA) Technology's diamond composite blades for coal field geological drilling adopt the leading sintering technology and are specially made for coal field/mining drilling bits, which have the advantages of fast feed, high efficiency, less chipping, economical and practical, etc. They are widely used in the fields of geological exploration, coal field drilling and mining.