With the continuous progress of industrial technology, the requirements for material processing precision and efficiency are increasing. Aluminum alloy, as a lightweight and high-strength metal material, has been widely used in aerospace, automotive manufacturing, electronic equipment and other fields. However, aluminum alloy is difficult to process, especially under the demand for high-precision and high-efficiency machining, traditional machining tools are often difficult to meet the requirements. The PCD discs produced by BN(CHINA) Technology, as a high-performance composite material, has shown great advantages in machining aluminum alloy.

Extremely high hardness and wear resistance

BN(CHINA) Technology PCD discs is made of diamond micropowder and alloy matrix sintered under ultra-high pressure and high temperature conditions, and its hardness is as high as about 10,000HV. This feature can easily cope with the hardness and toughness of the material when machining aluminum alloy, effectively reducing tool wear and extending service life. Compared with traditional cemented carbide tools, BN(CHINA) Technology PCD cutters have higher wear resistance, which can significantly reduce the frequency of tool change and improve productivity.

Excellent thermal conductivity

Aluminum alloy will generate a lot of heat during the machining process, if the heat can not be emitted in time, it will lead to high temperature of the tool and workpiece, which will affect the machining accuracy and tool life. BN(CHINA) technology PCD discs has extremely high thermal conductivity, better than silver, copper and other metals, much higher than the general cemented carbide. This characteristic can quickly export the cutting heat when machining aluminum alloy and keep the cutting temperature low, thus reducing the thermal deformation of the tool and thermal damage of the workpiece, and improving the machining accuracy and surface quality.

Low coefficient of friction and cutting forces

The coefficient of friction between the BN(CHINA) technology PCD discs and aluminum alloy is low, about 1/2 of that of cemented carbide. The low coefficient of friction not only reduces the cutting force during the cutting process and reduces cutting energy consumption, but also avoids the generation of chip tumors during cutting and further reduces the machining surface roughness. The use of BN(CHINA) technology PCD discs in the machining of aluminum alloys can achieve a smoother and more accurate cutting process and improve machining quality.

High machining precision

With low coefficient of thermal expansion and high modulus of elasticity, BN(CHINA) technology PCD discs is not easy to be deformed during the cutting process. Even under the action of larger cutting forces, PCD cutters can maintain their original parameters and stay sharp for a long time. This feature enables PCD cutters to achieve higher machining accuracy when machining aluminum alloys and meet the needs of precision manufacturing.

Flexibility and adaptability

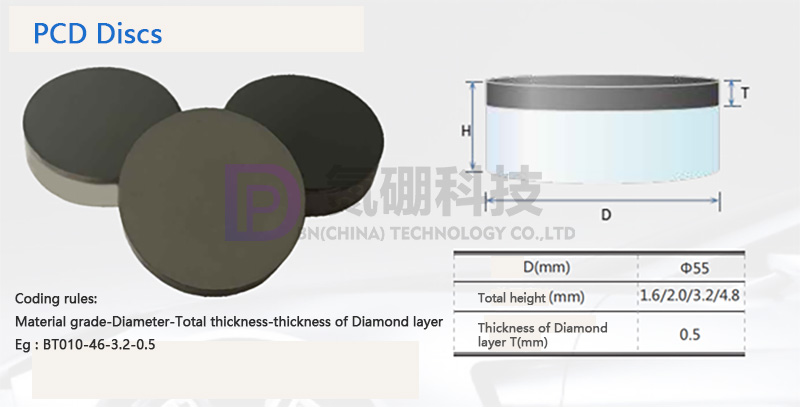

BN(CHINA) technology PCD discs can be formulated in different sizes and shapes according to the actual needs and are suitable for various machining scenarios. At the same time, the advanced manufacturing process of PCD cutters allows the design and prediction of the product's performance, giving it unique characteristics to suit specific machining needs. This flexibility and adaptability allows PCD cutters to cope with complex and changing machining tasks when machining aluminum alloys, improving productivity and flexibility.

To sum up, BN(CHINA) technology PCD discs shows great advantages in machining aluminum alloys, including very high hardness and wear resistance, excellent thermal conductivity, low coefficient of friction and cutting force, high machining precision, as well as flexibility and adaptability. With the continuous development of industrial technology, the application prospect of PCD discs in the field of aluminum alloy machining will be more broad.