Cubic boron nitride single crystal (CBN), is a synthetic superhard material, does not exist in nature, nitrogen atoms and boron atoms hybridized in sp3 way to form CBN, the atomic structure is similar to the structure of the carbon atoms in the diamond, has a high density and high hardness and other characteristics, CBN Moh's hardness of 9.7, is the hardness of the known superhard materials second only to the hardness of diamond (hardness 10).

CBN is divided into several different systems based on color, and yellow (amber, honey, yellow-brown), as well as brown and black (B-doped) are common in the market. Currently the synthesis of CBN single crystal is mainly by static high pressure catalyst method, usually using h-BN and different catalysts as raw materials to synthesize CBN single crystal under high temperature (1400℃-1800℃) and high pressure (4-8GPa).

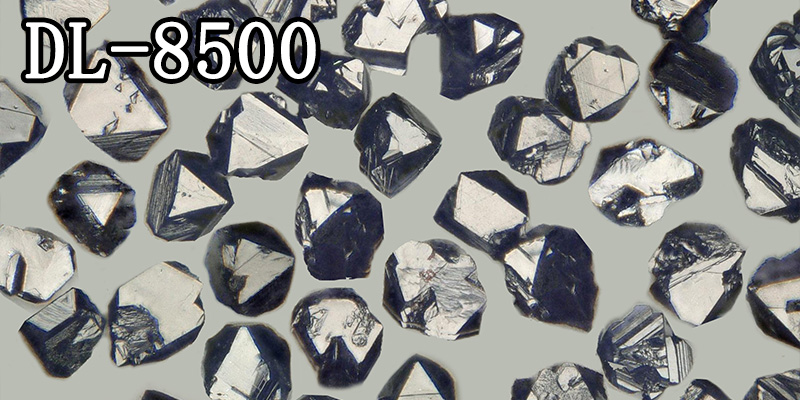

BN(CHINA) Technology latest black DL8500 series CBN single crystals, preferably high-purity h-BN, h-BN crystal structure is complete, low impurity content, the use of high-activity lithium-based multicomposite materials as the main catalyst, through many years of research and practice of the synthesis curve, the control of the synthesis temperature and make the cavity temperature distribution is uniform, to control the nucleation process, followed by high-pressure stage to complete the transformation and crystal growth from the hexagonal to the cubic phase, the synthesized black CBN single crystal has sharp edges, with more crystal faces, high impact toughness. Then the transformation from hexagonal phase to cubic phase and crystal growth are completed in the high-pressure stage, and the synthesized black CBN single crystals are sharp and angular, with more crystal surfaces and high impact toughness.

Black DL8500 series CBN single crystal has the highest impact strength in the industry among the same kind of products, good thermal stability, more crystal surfaces, more with clear angles, can be subdivided into A, B-type, A-type with a complete regular block morphology, cutting and grinding efficiency, with higher strength; B-type crystals are irregular block or flake morphology, high sharpness, self-sharpening good. Commonly used DL8500-A type CBN, such as 80/100 particle size Ti value of 81, TTi value of 76; DL8500-B type CBN, 80/100 particle size Ti value of 76, TTi value of 73.

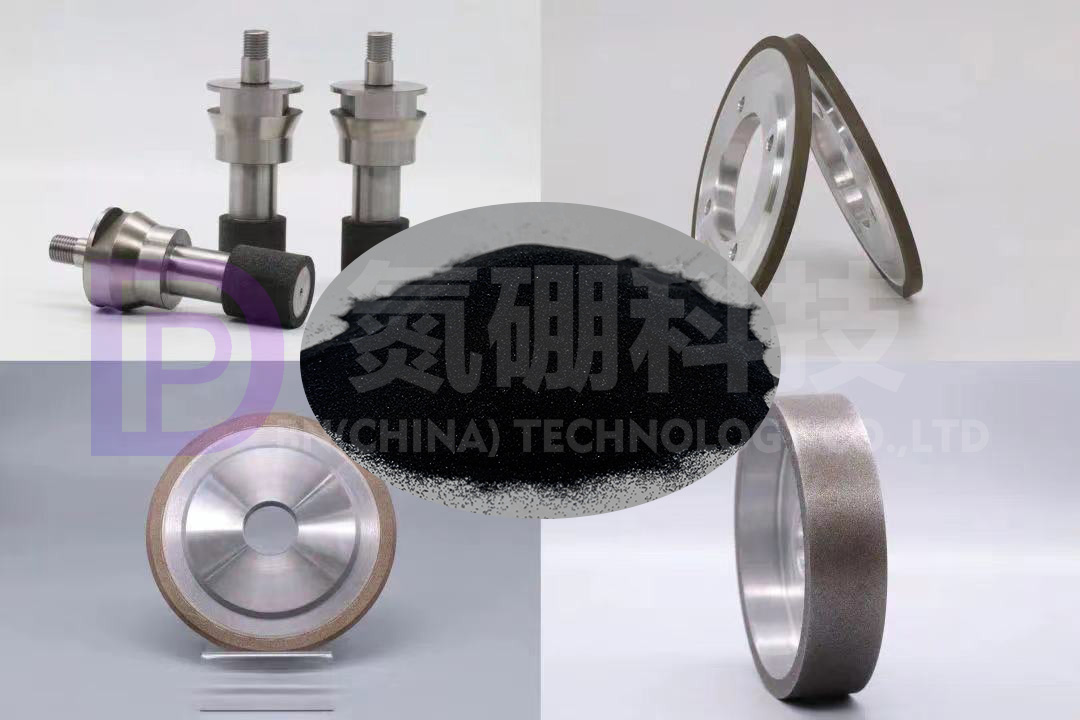

DL8500 grade black CBN single crystal can be used as abrasive materials, cubic boron nitride single crystal with the help of the bonding agent will be cubic boron nitride abrasive bonded into a product with a specific shape.CBN can be used in a variety of bonding agent system, such as metal, resin, plating, ceramics and so on. Can also be used for the production of polycrystalline composite materials, as well as abrasive particles and abrasive paste, etc. DL8500 grade black CBN single crystal crystal angular, so the use of black CBN single crystal made of grinding wheels, with good grinding performance, has a good self-sharpening properties, for the ferrous metals, especially high hardness, high toughness, high strength at high temperatures and low thermal conductivity of the material, high grinding efficiency, high grinding accuracy, made of CBN grinding wheels long life. CBN grinding wheels have a long service life.

DL8500 grade black CBN single crystal and ceramic bond sintered preparation, used for high-speed steel hob tooth grinding wheel, very good to maintain the shape of the hob precision, significantly improve the efficiency of the grinding process. Compared with the traditional corundum grinding wheel, the grinding efficiency can be increased by more than 30%. In camshaft processing, the ceramic bond CBN grinding wheel can work at a speed of 160m/s or more, and the beat of each shaft can be shortened by more than half compared with the 5min of ordinary grinding wheels in the industry.CBN grinding wheels are used in the applications of drilling and milling cutters, broaching cutters, automobile transmission shafts, rotor grooves of molding grinding and other industrial fields, and they have maintained the features of high grinding efficiency, high grinding precision and long service life. Characteristics.

Black CBN single crystals can also be used as cutting tool materials, generally using micron-sized CBN single crystal micro-powder, and the bonding phase by high-temperature and high-pressure sintering to prepare PCBN, in the field of metalworking has a huge application market.