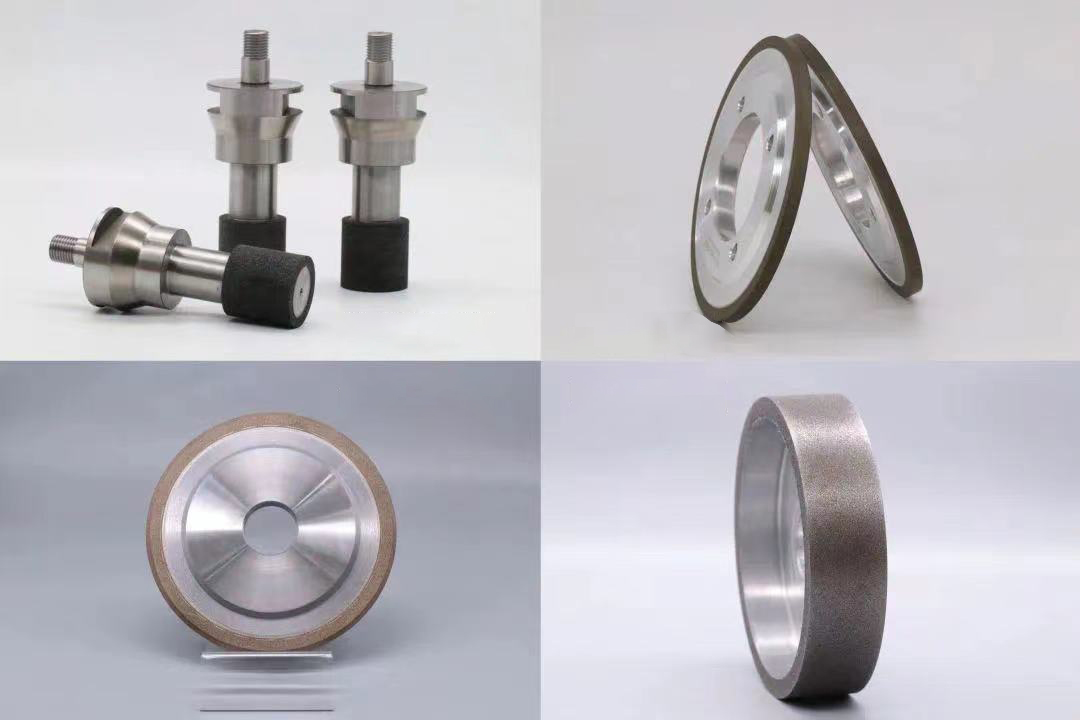

CBN, as a super-hard material, is often used to make grinding wheels of various sizes. There are many types of grinding wheels, according to the type of abrasive grain, in addition to super-hard abrasive CBN grinding wheels, there are ordinary abrasive (corundum and silicon carbide, etc.) grinding wheels, and diamond grinding wheels. According to the different combining agent, it is also divided into resin grinding wheel, ceramic grinding wheel, rubber grinding wheel, metal grinding wheel, etc., of which the most common are resin and ceramic grinding wheel, metal grinding wheel.

Three elements of the grinding wheel: abrasive grain, bond, and porosity.

Factors affecting the performance of the grinding wheel include: type of bond, type of abrasive grain, abrasive grain size, hardness of the wheel, concentration of the abrasive, and so on.

The role of the bond is to firmly bond the abrasive grains together to form a grinding wheel with a certain strength and hardness as a whole. The hardness of the grinding wheel varies greatly depending on the type of bond. Ceramic bond grinding wheels usually have high hardness and sharpness. During the grinding process, ceramic grinding wheels are able to maintain stable cutting performance and reduce heat generation and wear, thus extending service life. It is suitable for grinding high hardness and high toughness materials with higher hardness, good wear resistance and impact resistance.

Abrasive grains are sharp particles on the grinding wheel, which are the components that play a role in grinding. When the grinding wheel rotates at a high speed, the abrasive grains come into contact with the surface of the workpiece and generate friction, the size of which is determined by the depth of cut, shape of the abrasive grains, cutting speed and other factors. In this process, the abrasive grain cuts into the surface of the workpiece and removes the uneven part as chips, thus realizing the grinding process of the workpiece. The sharpness and hardness of the abrasive grains determine their ability to cut into the workpiece material, as well as the grinding ratio of the wheel.

Wheel grit size usually refers to the abrasive grain size used in grinding wheels, and different grit sizes have different grinding effects. When choosing the grit size of the grinding wheel, it is necessary to consider the production requirements. The larger the grit size, the greater the cutting speed, the greater the surface roughness of the workpiece, and the faster the abrasive wear. In rough grinding workpiece, the first thing is to consider the amount of material removal, it is appropriate to use coarse grit grinding wheel, can quickly grind out the general shape.

When processing workpieces with high hardness, coarse grinding wheels are generally used for rough grinding, and then fine grinding wheels are used for fine processing.

For softer materials, fine grinding wheels can be used directly, and the feed can be adjusted to achieve high efficiency and fine grinding according to production requirements.

When the workpiece requires higher processing precision, usually choose finer grinding wheels to achieve a higher degree of surface finish.

Different types of abrasive grains are suitable for processing workpieces made of different materials. Diamond grinding wheels have high hardness and good abrasion resistance, and are used for grinding hard alloys, ceramics, glass and other materials with high hardness and brittleness.CBN grinding wheels have high hardness and better thermal stability, and CBN does not have chemical reaction with iron elements, so they are suitable for processing ferrous materials with high hardness, such as quenched steel, high-speed steel, and so on.

BN(CHINA) Technology is a high-tech company integrating research and development, production, sales and service. our company produces cubic boron nitride products, the existing brown CBN: DL7800 and black CBN: DL8500 two grades. dl8500 black cubic boron nitride, with excellent impact strength, high thermal stability, crystal surface, angular, high grinding efficiency; DL7800 brown cubic boron nitride, with higher impact strength, crystal surface integrity, with laminar growth structure, both high life and grinding efficiency. DL7800 brown cubic boron nitride, with higher impact strength, complete crystal surface, with layer growth structure, both high life and grinding efficiency.