In the field of modern machining, PCBN (Cubic Boron Nitride) tools have become an important tool for efficient machining due to their excellent hardness and wear resistance. However, PCBN tools sometimes chipping occurs in the process of using, which brings a lot of trouble to the production. Today, we will analyze the causes of PCBN chipping and discuss the corresponding solutions.

01 Unreasonable cutting parameters

Cause of the problem

Too high a cutting speed may cause the tool to be subjected to excessive heat and impact instantaneously, thus causing chipping. Too large a feed will increase the cutting volume per tooth, overburdening the tool edge.

Solution

Optimize the cutting parameters, according to the characteristics of the processing materials and tools, select the appropriate cutting speed, feed and depth of cut. Find the best combination of parameters through testing and experience.

02 Improper tool installation

Problem Cause

The tool is not clamped during installation, which generates vibration during machining and easily causes chipping. The tool and machine spindle have different axes, which will lead to uneven distribution of cutting force and increase the risk of chipping.

Solution

Use a suitable fixture to clamp the tool firmly. Check the coaxiality of the tool and the machine spindle before installation and make necessary adjustments.

03 Problems with processed materials

Problem Causes

The presence of hard points, inclusions and other uneven components in the material can cause the tool to be subjected to excessive localized forces during cutting, triggering chipping.

Solution

Pre-treat the machining material to remove inclusions and hard spots in the material and improve the homogeneity of the material.

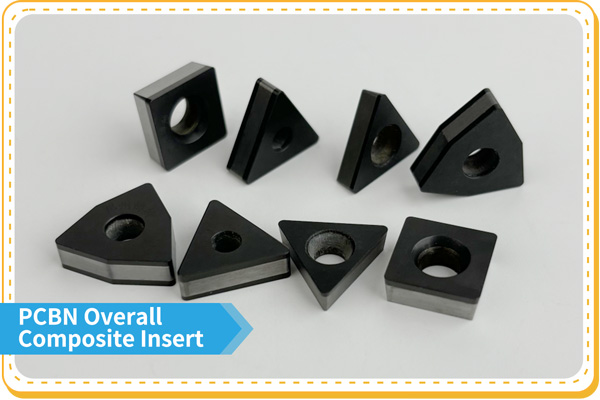

04 Tool arc, edge parameters and grinding quality

Causes of problems

If the arc of the tool and the edge parameter are not properly selected, the grinding quality of the tool edge will be affected. In addition, poor edge grinding quality, such as microscopic defects in the edge, micro chipping, etc., will reduce the strength of the tool and easily lead to chipping.

Solution

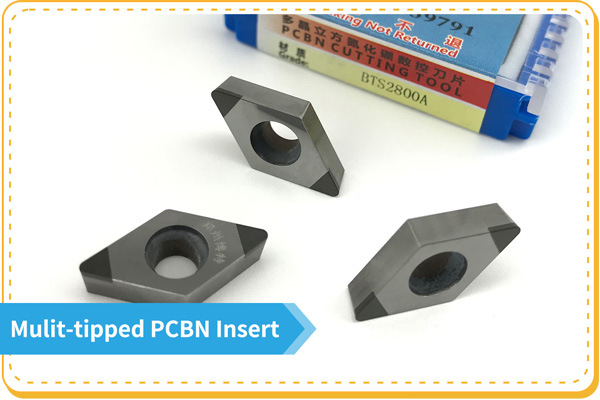

Select the appropriate arc and edge parameters according to the actual working conditions. Choose high quality PCBN tools, purchase from well-known manufacturers (such as Zhengzhou Berlt), reliable quality tool products.

In conclusion, to solve the problem of PCBN chipping, it is necessary to comprehensively consider a number of factors, from the optimization of cutting parameters, tool installation and selection, to the processing of machining materials and machine tool performance enhancement and other aspects. Only in this way can the advantages of PCBN tools be fully utilized to reduce production costs and improve machining efficiency and quality.

BN(CHINA) Technology through years of field machining experience that: the microstructure determines the macro performance, the failure of CBN inserts, are in the form of micro chipping failure, so by improving the surface quality of the inserts, mainly improve the surface quality of the cutting edge, can enhance the tool life and cutting stability.