Higher efficiency

Higher edge quality

Better consistency of inserts

Longer life

Advanced technology

Precise grinding PCBN&PCD inserts

Suitable for coarse grinding,

fine grinding and polishing.

Higher efficiency

Higher edge quality

Better consistency of inserts

Longer life

Advanced technology

Precise grinding PCBN&PCD inserts

Suitable for coarse grinding,

fine grinding and polishing.

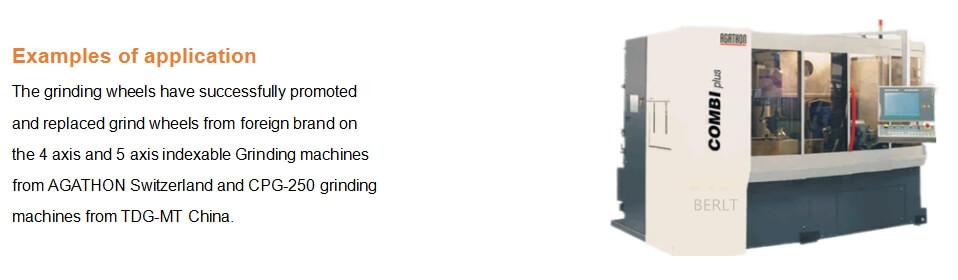

Introduction

The ceramic binder diamond grinding wheel has high strength, good heat resistance, sharp cutting, high grinding efficiency, it is not easy to heat and block in the grinding process, and the heat expansion is small, so it is easy to control the machining precision. Compared with the resin binder diamond grinding wheel, it solves the low life of the resin diamond grinding wheel, the low grinding efficiency and the easy deformation of the grinding tool itself in the grinding process.

Ceramic binder diamond grinding wheel has the common characteristics of diamond and ceramic binder:

1.Compared with ordinary corundum and silicon carbide grinding wheel, it has strong grinding force, low temperature and less wear of grinding wheel.

2.Can be adapted to the effects of various coolants;

3.The shape of grinding wheel is good and the precision of grinding workpiece is high.

4.There are more pores in the grinding wheel, which is beneficial to chip removal and heat dissipation, which is not easy to block and burn the workpiece.

5.The self-sharpening of grinding wheel is better, the time of dressing interval is long, and the dressing is easier.

| Insert type | Allowance(mm) | Manufacturer | Tac time(s) | Unit consumption(mm) | Insert quality |

SCMN090 | 0.2 | Berlt | 128 | 0.004 | No sawtooth, mirror surface |

| Other brand | 200 | 0.01 | |||

| 0.2 | Berlt | 180 | 0.0056 | No sawtooth, mirror surface |

| Other brand | 290 | 0.015 |

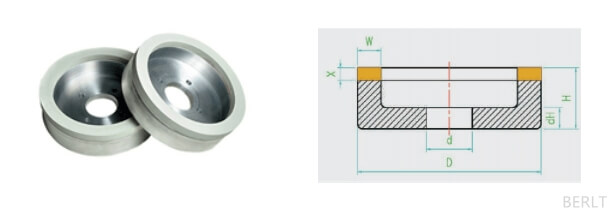

Suitable for the high -precision end/surface and cutter's grinding

Diameter (D) | Hole diameter(d) | Heigh (H) | Basal height (dH) | Disc width (W) | Grinding thickness(X) | Grain size | Concentration |

| 50 | 13 | 25 | 6 | 5,6 | 5,8 | Upon request | Upon request |

| 75 | 20 | 30 | 10 | 5,6 | 5,8 | ||

| 150 | 32,40 | 35,40 | 15 | 5,10,15 | 5,8,10 | ||

| 250 | 215 | 50 | / | 8,10,15 | 5,8,10 | ||

| Design and manufacture kinds of non-standard abrasive according the requirements. | |||||||

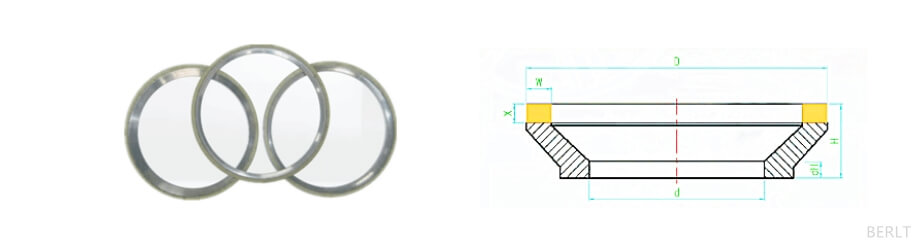

Vitrified diamond wheels specially for PCBN&PCD

Diameter (D) | Hole diameter(d) | Heigh (H) | Basal height (dH) | Disc width (W) | Grinding thickness(X) | Grain size | Concentration |

| 400 | 340 | 30 | 5 | 5,10,14 | 5,8 | Upon request | Upon request |

| 400 | 353 | 25 | 8 | 5,10,14 | 5,8 | ||

| 400 | 368 | 30 | 6 | 5,10,14 | 5,8 | ||

| 350 | 240 | 75 | 15 | 8,10 | 5,8 | ||

| 350 | 300 | 30 | 10 | 10 | 6 | ||

| Design and manufacture kinds of non-standard abrasive according the requirements. | |||||||

1. Q: Why customers choose us?

A: Attractive price, fast delivery, patiently pre-sales consultation and perfect after-sales service. Customized technical solutions for you. Strict quality system to inspect, samples and bulk goods every time.

2. Q: How long is your delivery time?

A: Generally it is 3-7 workdays if the goods are in stock. If customization is needed or out of stock, it takes 2-4 weeks.

3. Q: What is your terms of payment?

A: 30% T/T in advance ,balance before shipment. Or 100% T/T in advance.

4. Q:What is the payment method?

A: T/T, Paypal, Trade Assurance, Credit card

5. Q:Do you accept trial order?

A:Yes we do. You can order with small amount to test.

6. Q: Can we get a discount if our ordered quantity is big enough?

A: Yes, definitely right. We can offer you our best price and will give you a discount if your ordered quantity is big enough.

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.