Machinable Materials:

PCD, PCBN, carbide, high speed steel, cermet, ceramic, cast iron, magnetic material, stainless steel, glass, monocrystalline silicon, etc.

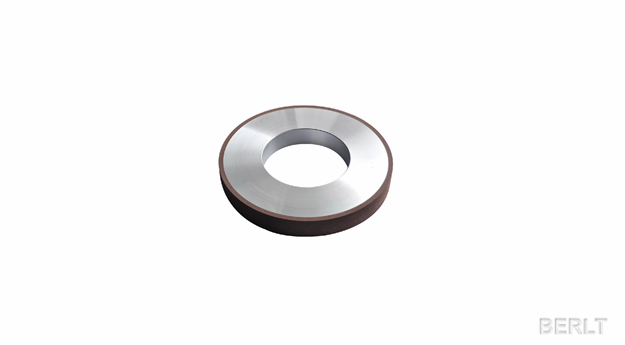

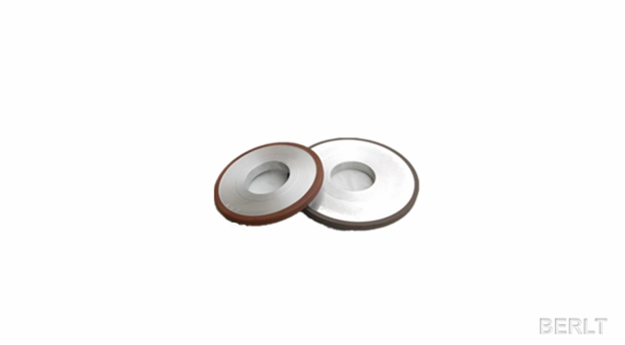

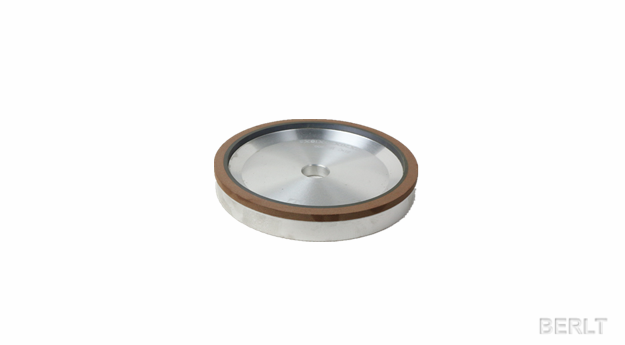

Grinding Wheel Model:

Various shapes: parallel grinding wheel, cup shape, bowl shape, dish shape, etc.

Models are customized base on the requirement of customers.