Features

Characteristic | Advantages |

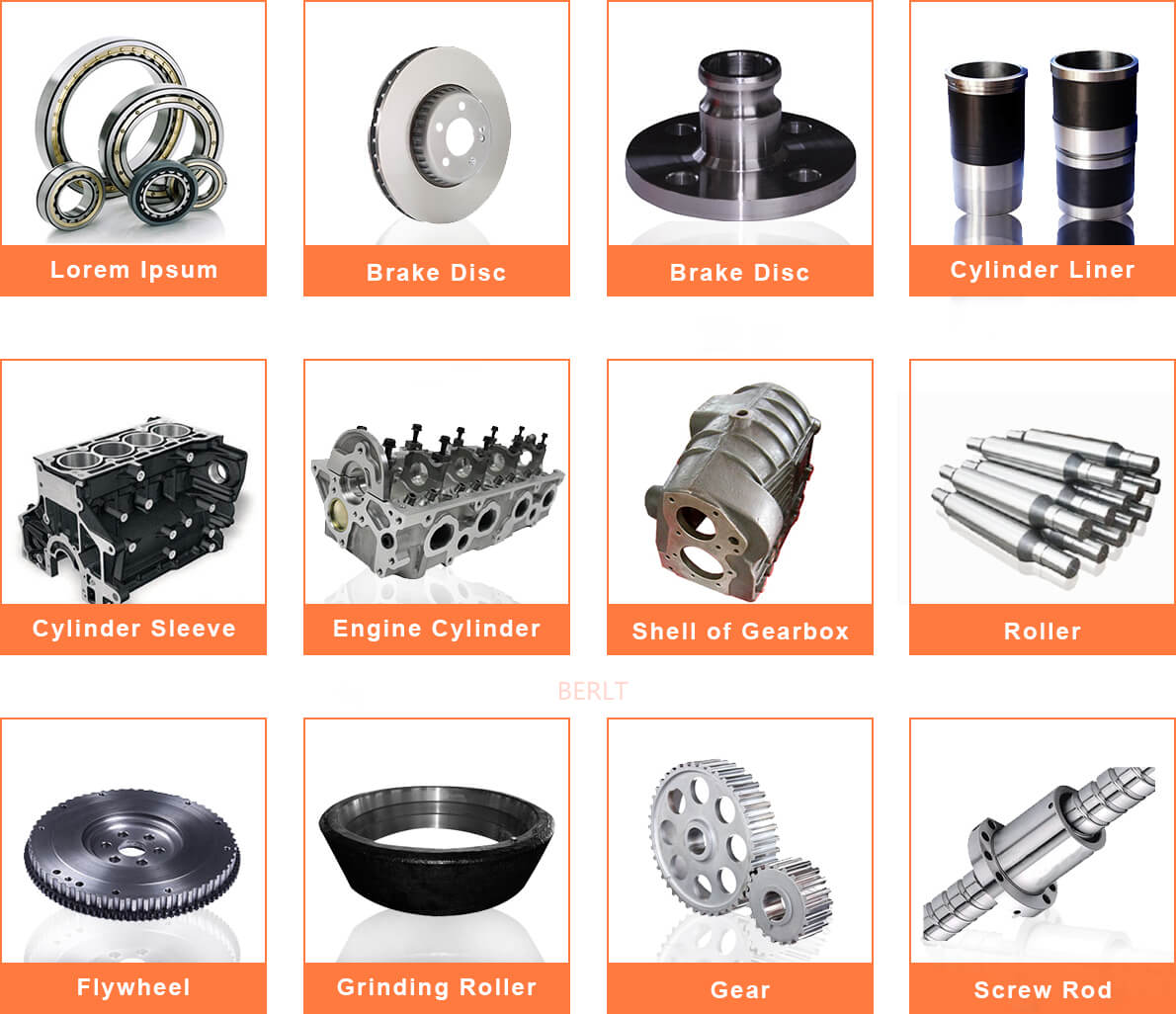

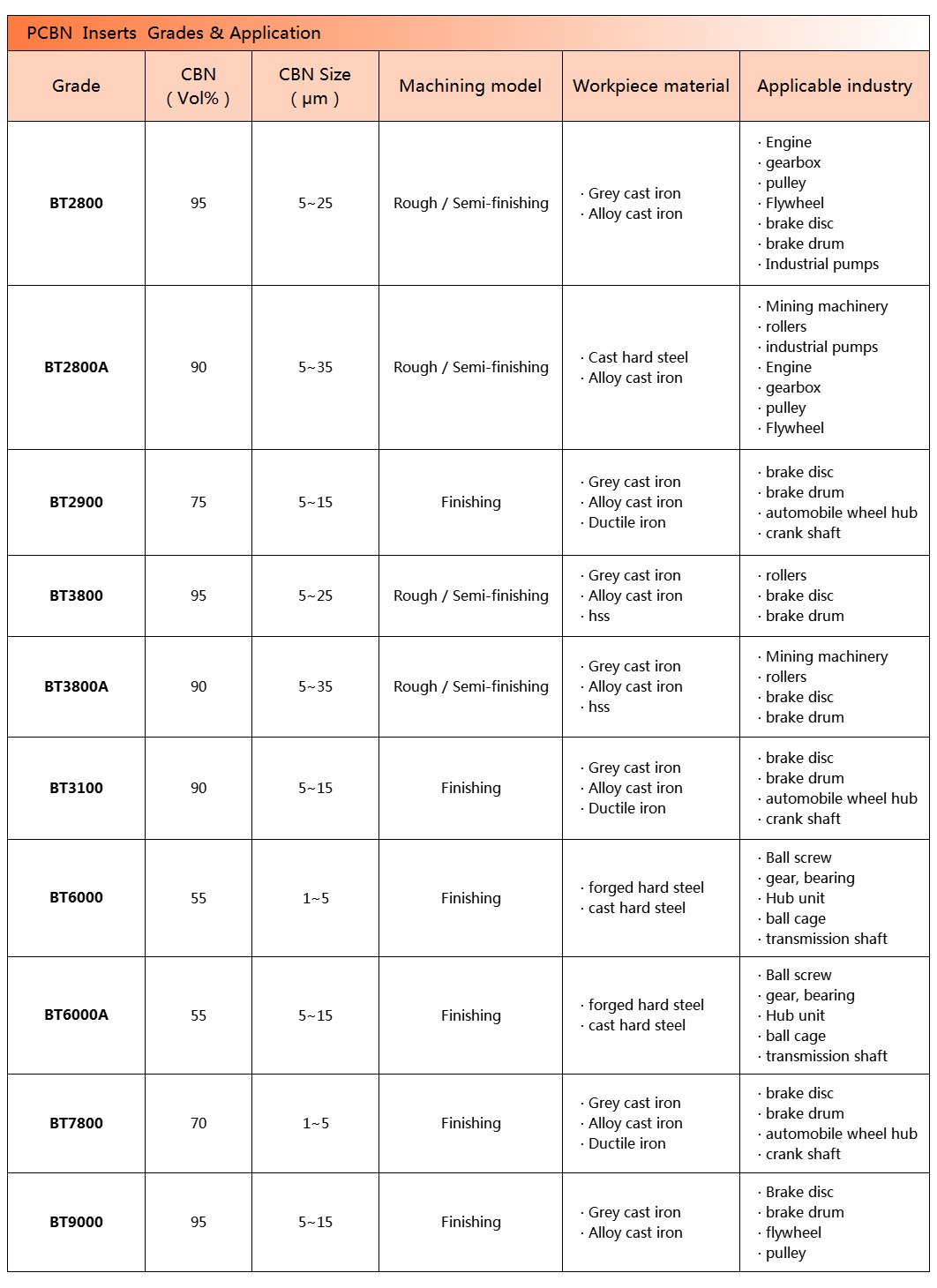

1.Widely application | Can meet finishing, semi-finishing and roughing. |

2.High fracture toughnes | Continuous cutting, general cutting, and interrupted cuttin |

3.High bending strength | Large cutting depth(<1/3 length of insert) |

4.High temperature resistanc | Can withstand high temperature of 1400 degree |

5.More cutting edges | Unlimited regrind, high blade utilization |

Precautions for the use of CBN inserts:

1.Polycrystalline cubic boron nitride tools are suitable for roughing and finishing of gray cast iron (iron content is not greater than 10%), alloy cast iron, chilled cast iron, high chromium cast iron, high manganese steel cast iron, quenched steel, surfacing and other workpieces with high hardness.

2.In use, different grades of tool materials should be selected according to different processing materials.

3.Before using the inserts, check whether the blade is installed correctly and the compression is firm, to avoid damage caused by improper compression and positioning of the inserts.

4.Make sure that the inserts are installed correctly on the machine.

5.When the blade is indexed, the sipe should be cleaned to ensure that the inserts and the blade are properly combined, and whether it is normal.

6.Care should be taken to check the sipes, gaskets, and pressure plates frequently, and if they are deformed or damaged, they should be replaced in time.

7.Before machining, it is necessary to chamfer the workpiece with a non-CBN tool.

8.During the cutting process, pay attention to the cutting status of the tool at any time. If abnormality is found, stop the machine and check immediately to avoid unnecessary damage.

9.Do not use CBN tools to cut the workpiece to the end, but leave a small margin for cutting with non-CBN tools.

10.When using CBN inserts, please pay attention to the rigidity of the machine tool, the vibration should be small, and the clearance of each transmission amplitude should be small.