Composite sintered diamond(referred to as CSD) is a new type of composite superhard material that is sintered into one body with diamond micropowder, binder (generally cobalt powder) and cemented carbide liner at high temperature and ultra-high pressure (1300~1500℃, 5~7GPa). The material takes into account the characteristics of diamond and cemented carbide, and also has the incomparable advantages of cemented carbide:

1, high hardness: the hardness of diamond composite sintered body is as high as about 10000HV, which is the highest hardness among the man-made materials at present, while the hardness of cemented carbide is only 1000-1800HV.

2, High wear resistance: extremely high and isotropic hardness, the wear ratio is more than 300,000, while the wear ratio of cemented carbide is less than 100.

3, good thermal stability: heat-resistant temperature up to 750 ℃, in the high temperature environment, can still maintain its performance stability, can be used in some of the higher ambient temperature scene.

4, good impact toughness: diamond composite sintered body impact toughness and cemented carbide similar, as a rock-breaking tool in the coal field geological drilling, oil and gas drilling and other operations, can withstand a larger impact, so that the drilling work can be sustained and stable, reduce the damage and failure caused by impact.

5, low friction coefficient: diamond and non-ferrous metal friction coefficient of 0.1-0.3, lower than the friction coefficient of cemented carbide and non-ferrous metal of 0.3-0.6, so that in the machining process cutting resistance is small, the machine tool load is small, not only to improve the surface quality of the processed workpieces and dimensional accuracy, and also reduce the machine tool loss.

6, high thermal conductivity: diamond's thermal conductivity is 2000W/m・K, 3 - 7 times that of cemented carbide, it can quickly conduct the heat generated in the cutting process, reduce the temperature of the cutting zone, further improve the durability of the cutting tool, and is also conducive to maintaining the performance of the processed material.

7, small coefficient of linear expansion: diamond composite sintered body of the coefficient of linear expansion of about (1.0 ~ 3.0) × 10 - ⁶ / ℃, is 1/4 of the cemented carbide, in the use of the process of the temperature is less affected, so it can maintain a higher dimensional accuracy.

Diamond composite sintered body is mainly used in the following fields:

1, drilling field:

Diamond composite sintered body has very high hardness, high impact toughness, especially suitable for soft to medium-hard geological rock layer drilling, has the advantages of fast drilling speed, good abrasion resistance, long life, etc., and the adaptability of the working environment to meet a variety of complex environments in the drilling, can greatly improve the drilling efficiency. Widely used in coal field mining, geological exploration, oil and gas drilling and other fields, the common drilling teeth tooth structure are: flat, spherical, conical and so on.

2. Mechanical processing:

Utilizing the excellent thermal stability and extremely low friction coefficient of diamond composite sintered body, the tools made of it can be used for cutting stone, wood, ceramics, plastics, rubber and other non-metallic materials and non-ferrous metals and their alloys, which not only enable the processed workpieces to obtain high surface finish and dimensional accuracy, but also take into account the ultra-high service life and machining efficiency.

3, Wear-resistant bearings:

Diamond composite sintered body has won wide application in the field of wear-resistant bearings due to its excellent wear-resistant performance. It can effectively extend the service life of bearings, improve the precision of bearings, show strong adaptability to harsh environments, and reduce maintenance costs. Especially in the field of mining machinery, aviation engines and precision instruments, diamond composite sintered body is widely used as wear-resistant bearings.

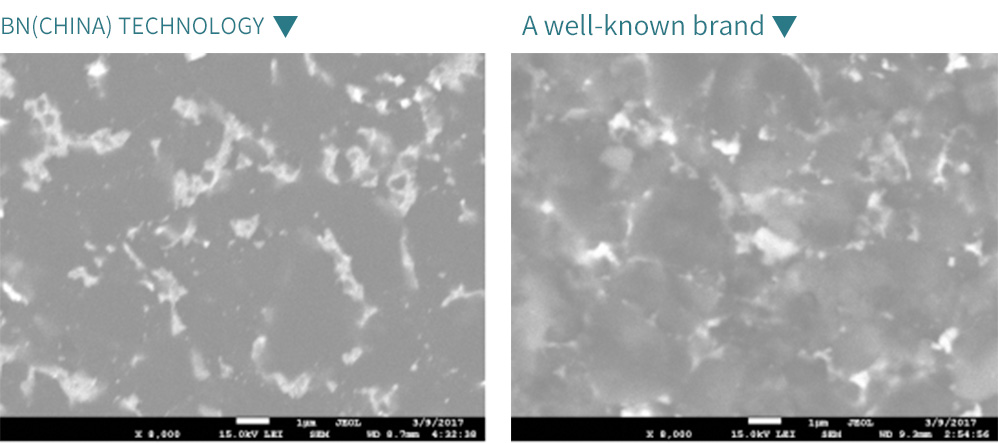

BN(CHINA) Technology Ltd. is a high-tech enterprise integrating scientific research, production, sales and service. The diamond composite sintered body produced by NBT is characterized by the fusion growth between diamond particles, the formation of close D-D bonds, high bonding strength, close bonding at the material interface, no stress and no defects, and a microstructure comparable to that of foreign products, as shown in the figure below.

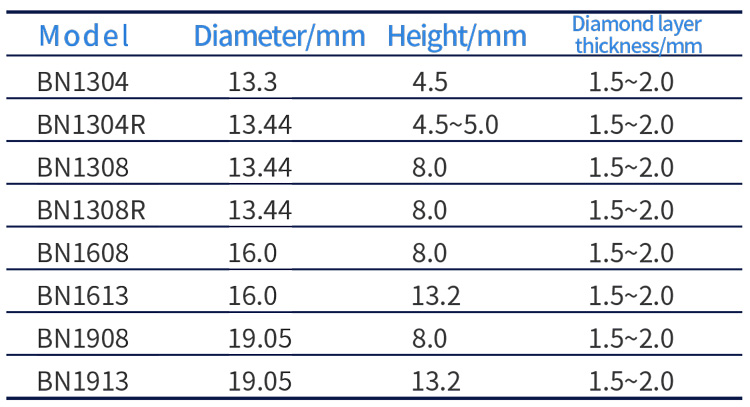

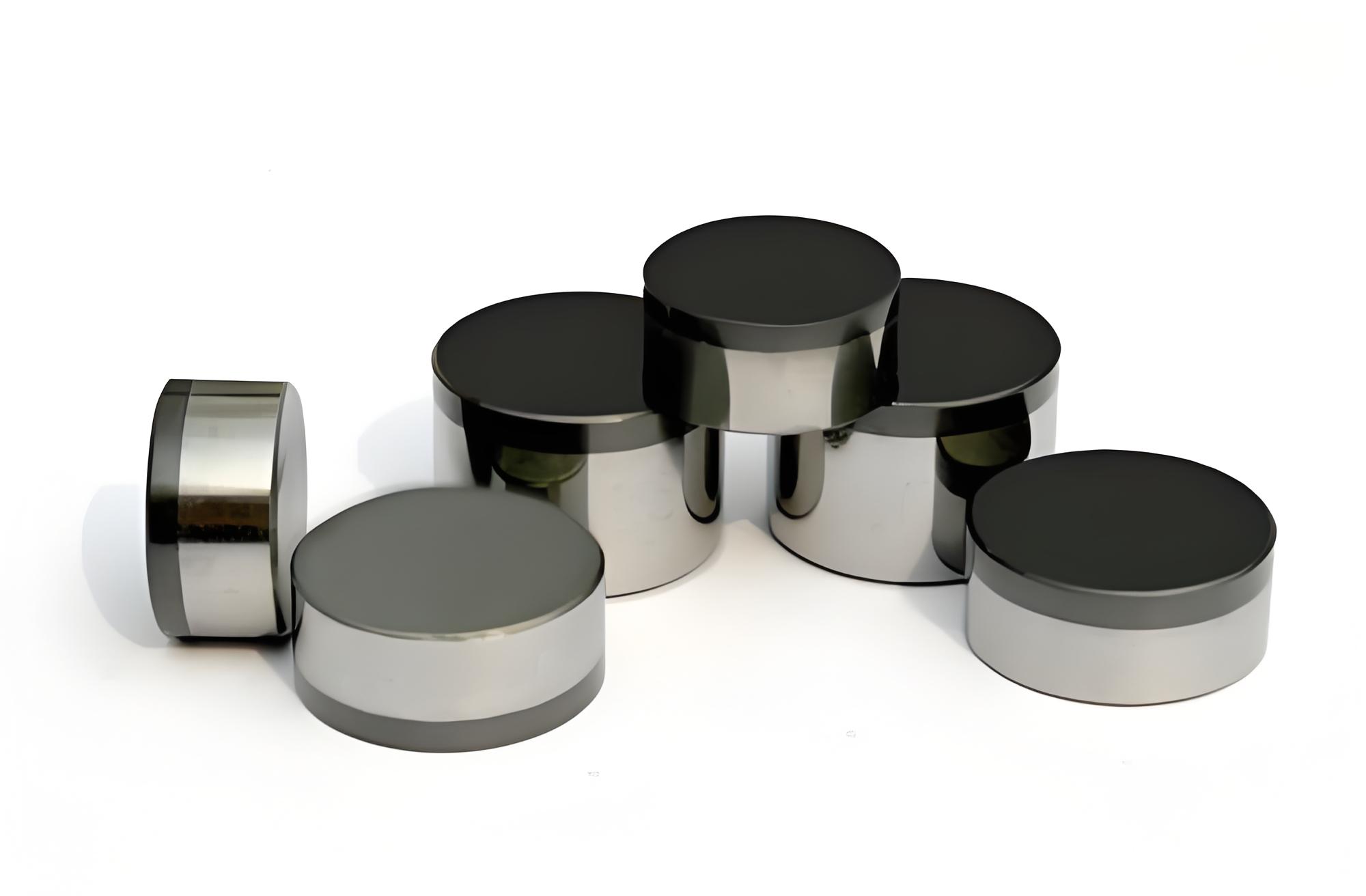

BN Technology's large-scale batch synthesis equipment guarantees the consistency and stability of product quality as well as supply capability. At the same time, Boron Technology has a wide range of products to meet the needs of different fields of application, and has the performance of high-grade products but has the price of mid-range products. Boron Technology diamond composite sintered body-rockbreaking tool teeth are available in the following models: