The performance of CBN grinding wheels, including machining surface quality, efficiency, durability and applicable rotational speed, is significantly affected by the abrasive grit size. Therefore, choosing the right CBN abrasive grit size is the key to achieving ideal processing results. So, what does CBN abrasive grit size mean? And how to make a choice?

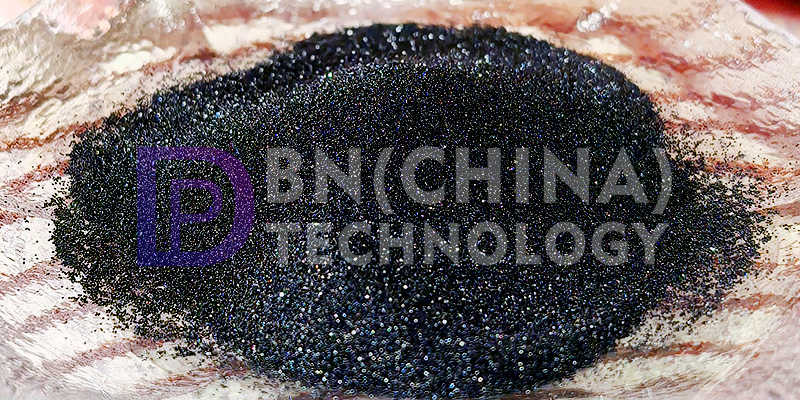

Strictly speaking, CBN abrasive grain size refers to the “grain size composition”. We often say “80/100”, “100/120” and other signs are called grit number, they represent a specific range of grit sizes, this range contains the coarsest grain, coarse, basic, fine and the finest grain. Grain size number is to distinguish the abrasive material coarse and fine mark, according to China's national standards, using the sieve method for determination. For example, CBN 100/120 is a particle size number with a nominal sieve size range of 125~150 μm, specifically referring to those abrasive particles that can pass through the 150 μm sieve mesh but at the same time are retained by the 125 μm sieve mesh. Within this size range, coarse particles are those that remain on the upper screen; basic particles are located between the upper and lower screens and are the main part of the size composition; fine particles are those that pass the lower screen but are retained by the lower limit screen; and the finest particles are those that can pass the lower limit screen.

CBN abrasive grit size directly affects processing quality, especially surface roughness. Several key factors need to be considered when choosing the right grit size number. Comparison of ordinary abrasives and roughness requirements: Due to the higher sharpness and wear resistance of CBN abrasives, to achieve the same surface roughness as ordinary abrasives, the grain size of CBN usually needs to be selected as fine as 1~2 grit sizes. On the contrary, if the surface roughness requirements can already be met, the coarser grit size should be prioritized to improve processing efficiency. Secondly, the type of bond is crucial: for resin bond CBN wheels, grit sizes of 100/120 and finer are recommended; for metal bond CBN wheels, grit sizes between 80/100 and 270/325 are recommended; and for ceramic bond CBN wheels, grit sizes can be selected between the commonly used range of grit sizes for resin and metal bonds. Processing conditions are the basis for the actual selection: in the rough grinding (large grinding allowance, grinding depth), the coarser grit size should be selected; while in the fine grinding (small grinding allowance, high precision requirements), the finer grit size should be selected.

It should be emphasized that, as one of the three elements of abrasives, the stability of the quality of the abrasive is the basis of the stability of the performance of the grinding wheel. In the selection of abrasives, in addition to the grain size of this key parameter, but also must take into account its impact toughness, crystal shape, single-grain strength and other important technical indicators, in order to ultimately select the most suitable abrasive.