Machining parts: face and inner hole

Workpiece material: 20CrMnTi

Hardness: HRC58-62

Insert: CBN overall composite insert

While controlling gear processing costs, how to achieve efficient, high-precision and high-stability processing is the driving force and goal for the automobile manufacturers to compete. The processing technology of automotive transmission gears is mainly divided into soft tooth surface processing and hard tooth surface processing . Soft tooth surface processing generally adopts hobbing → shaving → heat treatment process, and hard tooth surface processing adopts hobbing → heat treatment (carburizing) → grinding process.

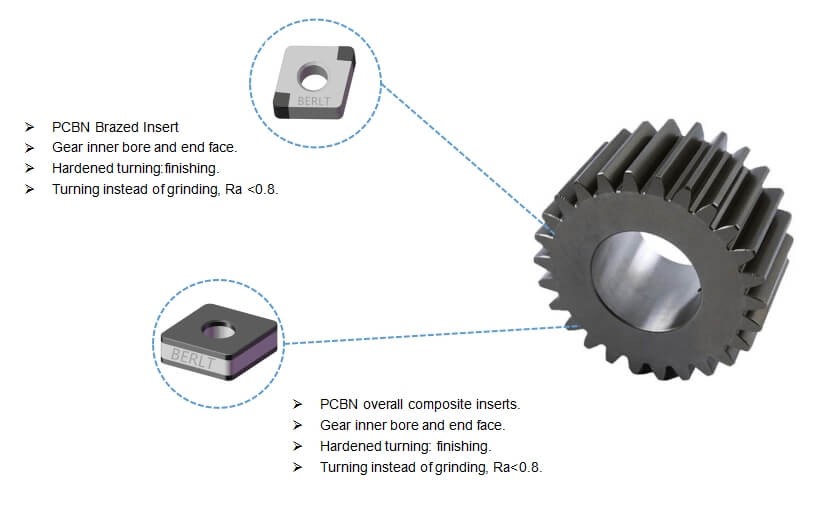

At present, in response to the requirements for high-efficiency, high-precision and high-stability machining of automotive transmission gears, in 2004, Danpeng integrated PCBN overall solid inserts, which successfully applied to the intermittent processing of large gear hard tooth surface (HRC62), it realized that turning replacing the grinding technology, which greatly improved processing efficiency.

In addition, Danpeng has made new breakthroughs in car gear carburizing and quenching of end faces, inner holes, tapered surfaces of synchronous meshing gears, and hard turning of gear shafts. The developed PCBN overall double-sided composite inserts have been successfully used in this field, and the technology is very high.

The CBN inserts with materials BT7600、BT7800、BT2800、BT6000 from Danpeng are widely used for HRC50-HRC79 gear carburizing and quenching, cast iron brake discs, air conditioning refrigeration pre-shrinking machines and other industries,It solves the problems of low efficiency and high cost of carburizing and hardening parts of ceramic blade precision turning gears. It is difficult to guarantee the precision and shape tolerances of the precision turning of the blades, and the CBN inserts have high durability. Most of them belong to normal wear and tear during use. The phenomenon of chipping is less, and the hardened parts with high hardness between turning, milling, boring, and grooving finishing HRC45-HRC68 make a great contribution.

As the tool manufacturer for the gearbox processing of automotive transmissions, Danpeng provides cutting CBN tools for internal bores and end faces of gears, gear shafts, coaxial fork grooves, etc. Performance, can meet the processing needs of more users, and develop to a larger processing range.

PCBN Brazed Inserts Finishing Gear Inner Bore

Inserts Manufacturers | Coated Ceramic Blade | BN Inserts |

Workpiece name and Materials | 20GrMoTi(HRC58-63) | |

Processing Position | Inner Bore | |

Inserts Model | CNGA120408 | CNGA120408-ZH |

Cutting Depth (mm) | 0.5 | |

Linear Velocity(m/min) | 150 | |

Feed(mm/r) | 0.5 | |

Inserts Life(pieces/edges) | 60 | 164 |

Processing Quality | Ra1.2 | Ra0.8 |

Remark: BN inserts life is 73% longer than customer's inserts life. | ||

PCBN Brazed Inserts Finishing Gear Face

Inserts Manufacturers | Other CBN Inserts | BN Inserts |

Workpiece name and Materials | 20GrMoTi(HRC58-63) | |

Processing Position | End Face | |

Inserts Model | CNGA120404 Coated | CNGA120404-ZH Coated |

Cutting Depth (mm) | 0.2-0.3 | |

Linear Velocity(m/min) | 80 | 120 |

Feed(mm/r) | 0.08 | 0.12 |

Inserts Life(pieces/edges) | 200 | 200 |

Efficiency | 1 | 2.25 |

Processing Quality | Ra1.6 | Ra1.6 |

Remark: The efficiency has been improved by 125%, meeting the process requirements, and the customer is very satisfied | ||

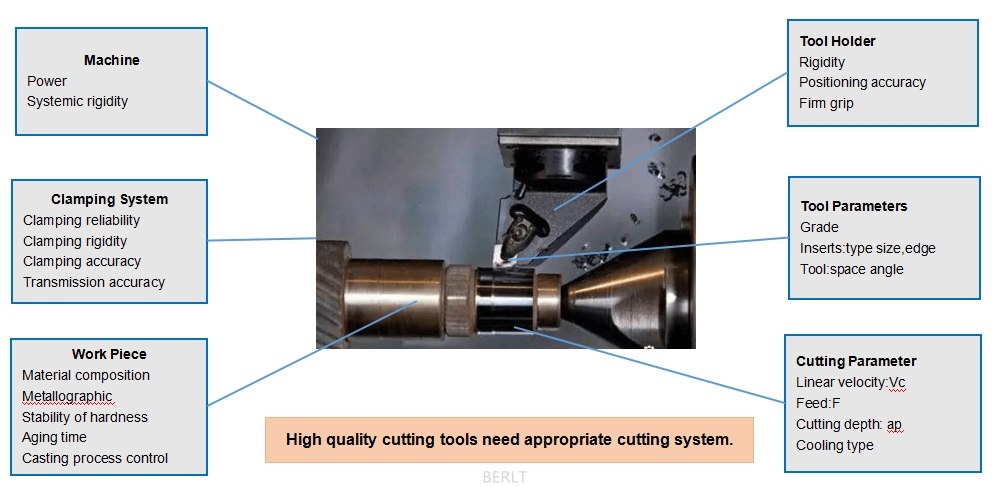

Factors that affect machining effect of PCBN insert